Difference between revisions of "project03:P1"

| Line 23: | Line 23: | ||

<p> | <p> | ||

<h2>Robotic production of envelope elements</h2><br> | <h2>Robotic production of envelope elements</h2><br> | ||

| − | a computational approach TOWARDS | + | a computational approach TOWARDS a climatically optimised building<br><br> |

'''CONTEXT'''<br> | '''CONTEXT'''<br> | ||

Revision as of 15:24, 24 February 2019

Robotic production of envelope elements

a computational approach TOWARDS a climatically optimised building

CONTEXT

Globally the population is growing dramatically. Around 1950 the world population was estimated at around 2.6 billion people. Reaching 5 billion around 1987, 6 billion in 1999 and since October 2011 it was estimated around 7 billion. Due to higher survival rate to reproductive age and major changes in fertility rates,

increasing urbanization and accelerating migration. It is estimated the world

population will reach around 8.5 billion in 2030. *1

All of these people have a need for a dwelling, increasing the demand of the

already scarce land and resources available. As is the case in the Netherlands. By 2030 it is estimated that there is an extra need of 1 million homes.

PROGRAMME

Currently there is a gap between the need for standardization to keep the cost down and the need for product customization that satisfies the diverse demands from consumers. Simultaneously more types of consumers are entering the market and more consumers want to have a higher degree of customization of their dwellings. *2 So not only is there an increasing need for more dwellings, there is also a need for more customized homes. With this graduation project I aim for mass produced customized dwellings.

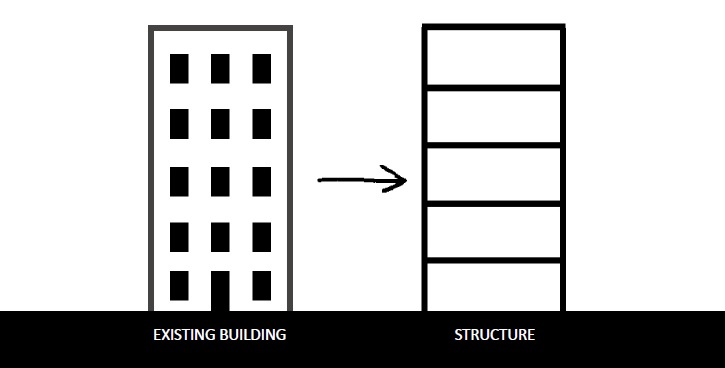

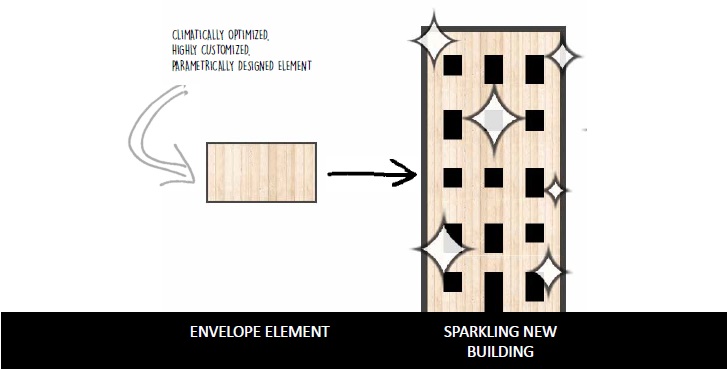

The existing building stock in the Netherlands has enough square meters available to provide for the need in dwellings. I therefore propose to use an existing

building, strip it down to it’s structure and convert it into dwellings. Emphasizing the development of the (parametrically designed) envelope with an optimisation towards the climatic plan. (exact location and program to be defined)

TECHNIQUE

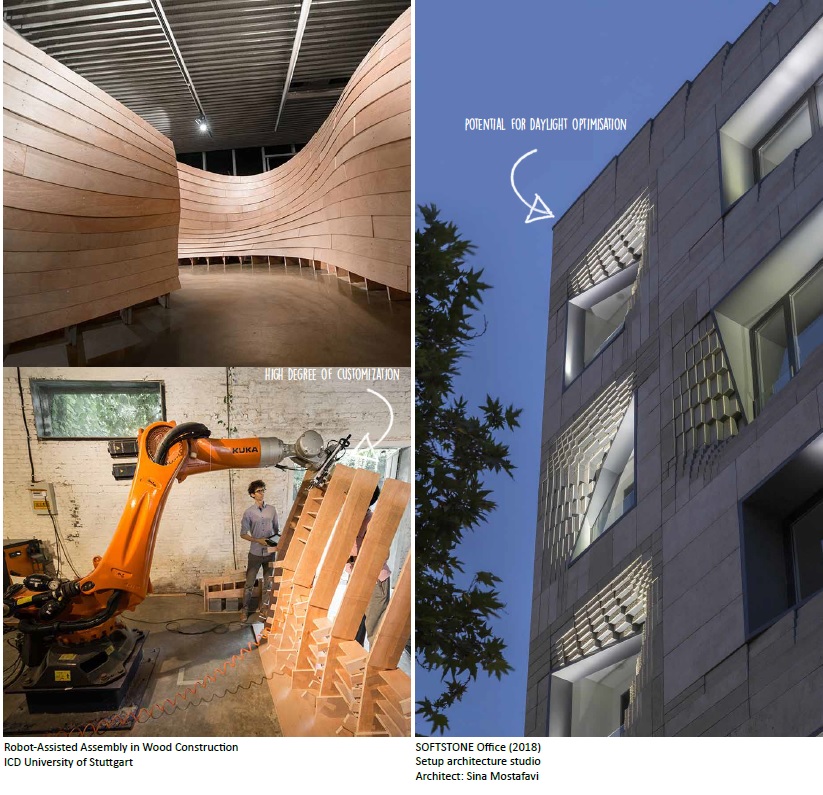

To bridge the gap between a certain standardization for mass production and the need for customization I propose a high-tech solution where robotic production and assembly technologies will build the envelope elements. Trying to utilize the full potential of robotic building while still collaborating with people in the

construction process. Keeping circularity and sustainability in mind, this

graduation project starts with a focus on wood as the main building material. For building with wood requires less energy and emits a lot less CO2 compared to steel or concrete.*3

“Timber construction has an impressive history of using CNC manufacturing

possibilities, but robotic assembly technologies are still very rarely integrated.”

Philipp Eversmann, Digital Fabrication course ETH Zurich

In short, this graduation project is about robotically producing and

assembling parametrically designed envelope elements. Elements that are integrated into the climatic design, mounted onto an existing structure.

Reseach question: How can robotic production and assembly technologies be

integrated in the making of envelope elements and their climatic design?

REFERENCE PROJECTS

- 1 United Nations on Our Growing Population, source: http://www.un.org/en/sections/issues-depth/population/

- 2 Mass-Customization in Housing: Designing Systems Rather than Objects by Nadia M. Anderson Iowa State University (2009)

- 3 Chadwick Dearing Oliver, Nadal T. Nassar, Bruce R. Lippke & James B. McCarter (2014) Carbon, Fossil Fuel, and Biodiversity Mitigation With Wood and Forests, Journal of Sustainable Forestry, 33:3, 248-275