Difference between revisions of "project03:P4 2"

| Line 24: | Line 24: | ||

<br> | <br> | ||

| + | <p>Summary | ||

| + | As housing prices keep skyrocketing in the city of Amsterdam in 2020, the affordability of dwellings for an average family become less and less. Families are moving out of the city due to a lack of space, affordability, and greenery. Yet these families are important to have within a city for its social diversity. They fulfill local jobs and invest into the local economy due to the needs of their children. The city of Amsterdam can offer a highly connected location towards friends, family, and work. Supermarket, library, and inner city all closely connected. Thereby saving commuting time in their already busy lives. <br><br> | ||

| + | This graduation project focuses on creating small yet spacious dwellings. Offering unique dwellings to live in. Designed and build with a robotic design and assembly strategy. Creating commercial areas on the ground floor, with dwellings above it. Separating dwellings for these families from the public and increasing the feel of safety for them. While still maintaining a strong connection with the park on the south. The volumes of these dwellings have been distributed by a computational model, based on solar and view performances. Locating sleeping areas in climatic colder regions, while placing the living areas opposite of that. <br><br> | ||

| + | The interior offers an acoustically optimized wall to reduce noise produced by for example children. Integrating the interior paneling with that of the exterior with a spiderweb-like structure. This structure is optimized by their local forces, and thereby minimizing a material need. Throughout this structure the windows are placed that line up in between the steel tubes. Thereby providing sufficient daylight for all the spaces. Certain windows are still being able to be opened and closed manually, thereby increasing living comfort. The negative spaces between the dwellings are used for routing the electrical, pluming and ventilation. Integrating a high degree of customization with the practical needs associated with building dwellings. As last a robotic assembly strategy is being shown in combination with a local optimized node. Integrating a ‘off the shelve’ solution combined with a customized 3D printed metal node. | ||

| + | </p> | ||

[[File:Diagrams.jpg|800px]]<br><br> | [[File:Diagrams.jpg|800px]]<br><br> | ||

Revision as of 20:15, 28 September 2020

Summary

As housing prices keep skyrocketing in the city of Amsterdam in 2020, the affordability of dwellings for an average family become less and less. Families are moving out of the city due to a lack of space, affordability, and greenery. Yet these families are important to have within a city for its social diversity. They fulfill local jobs and invest into the local economy due to the needs of their children. The city of Amsterdam can offer a highly connected location towards friends, family, and work. Supermarket, library, and inner city all closely connected. Thereby saving commuting time in their already busy lives.

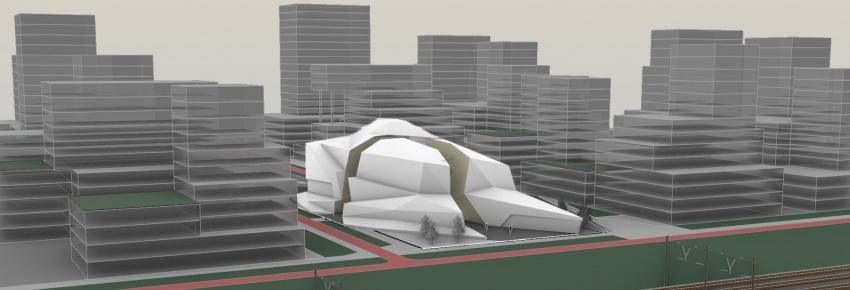

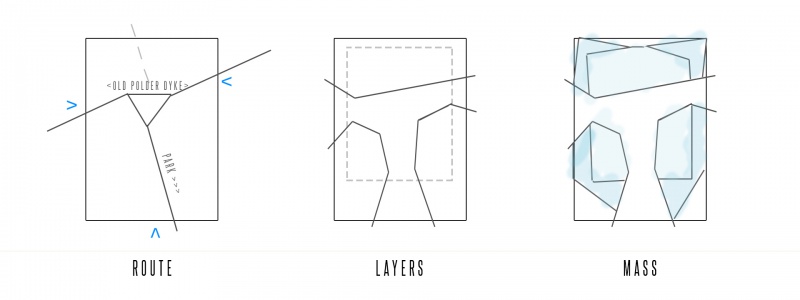

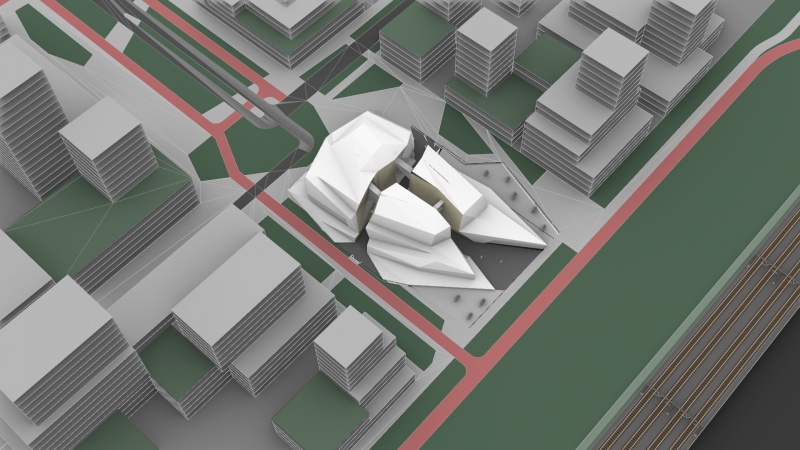

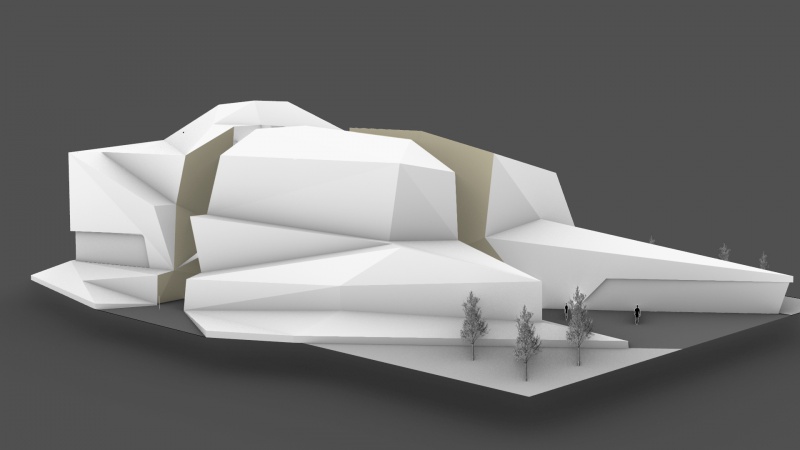

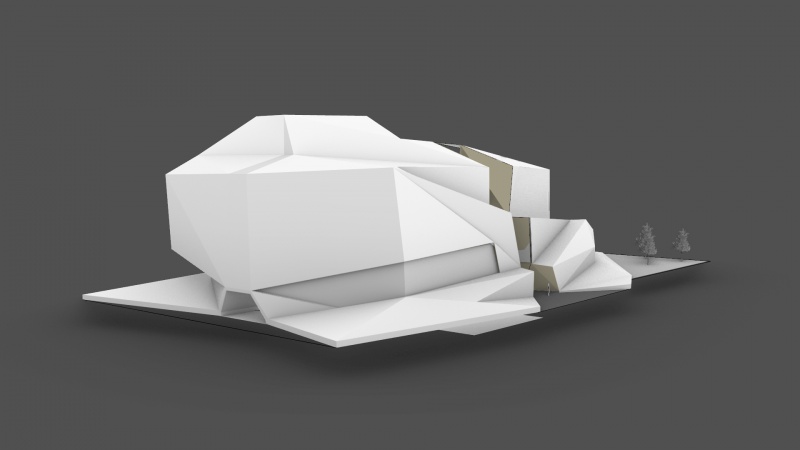

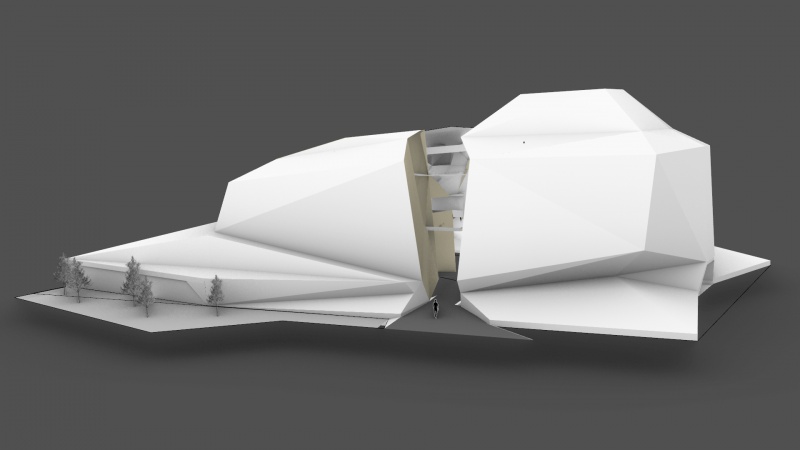

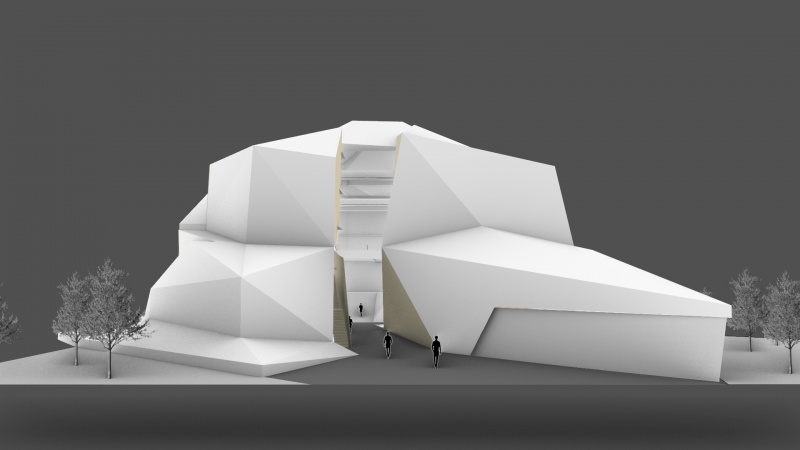

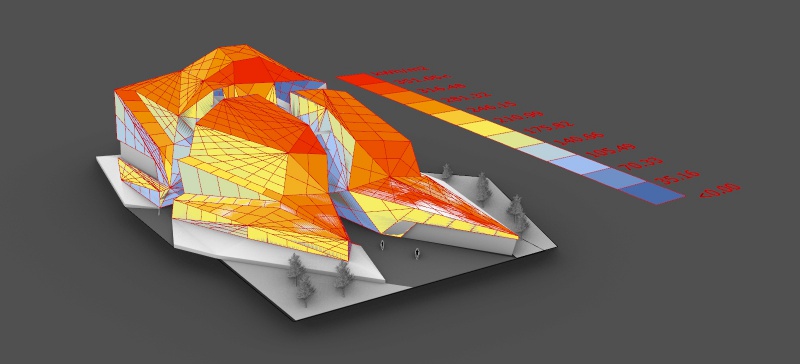

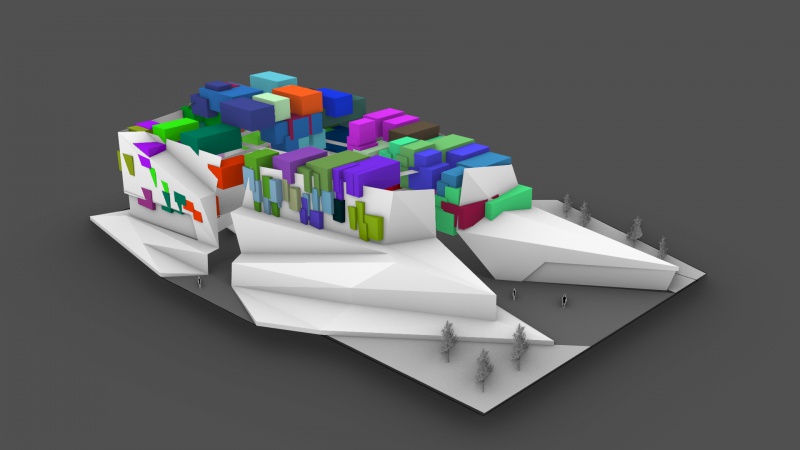

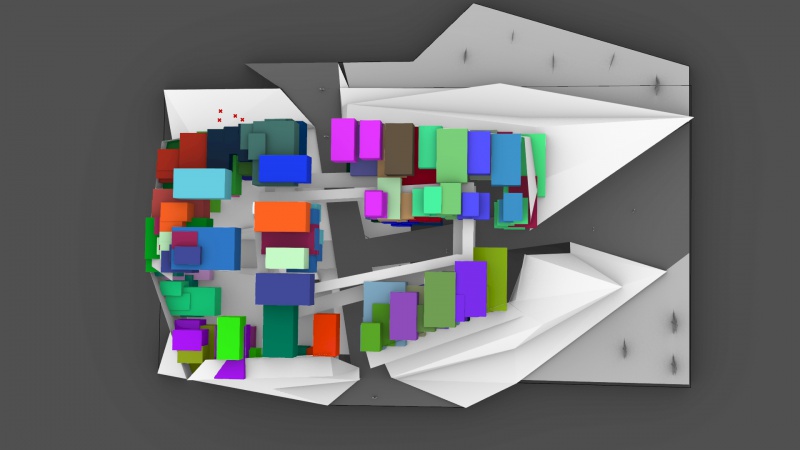

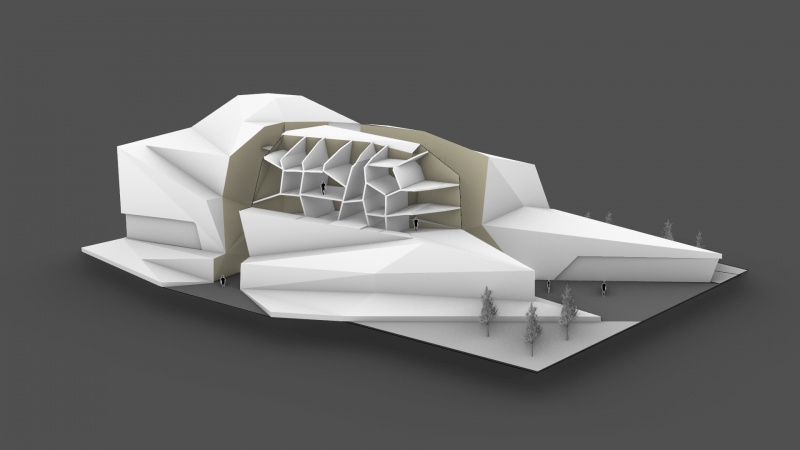

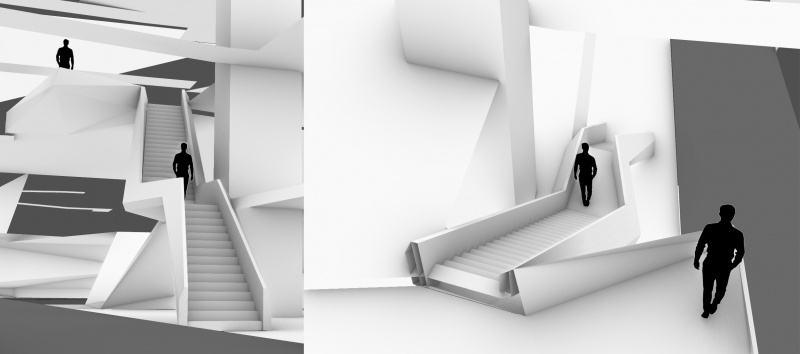

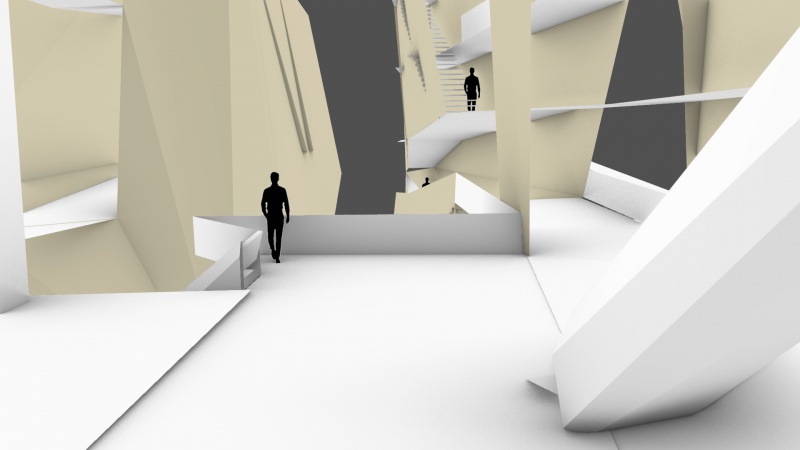

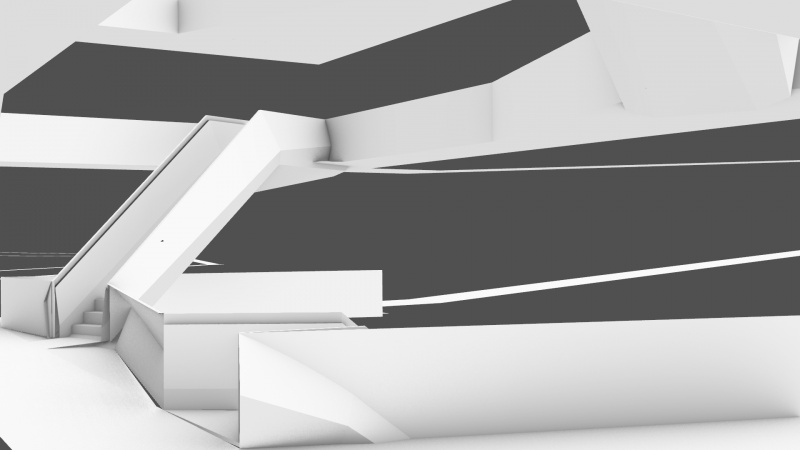

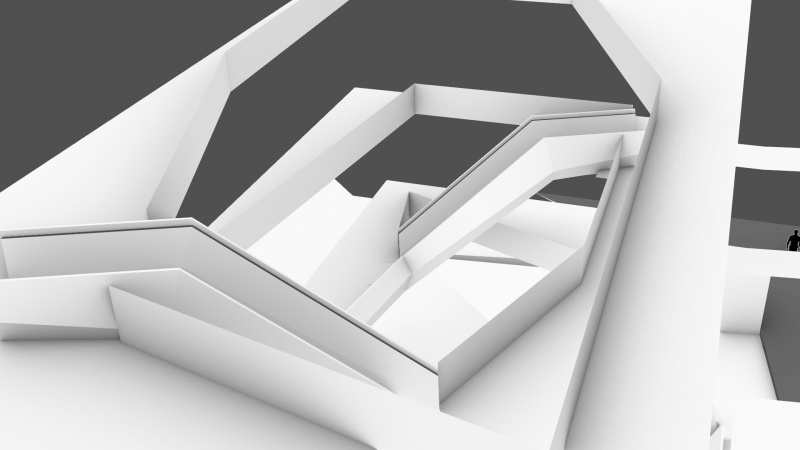

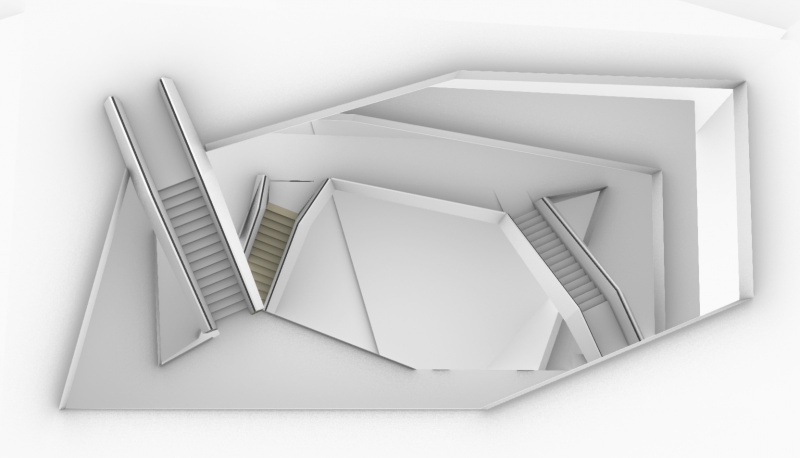

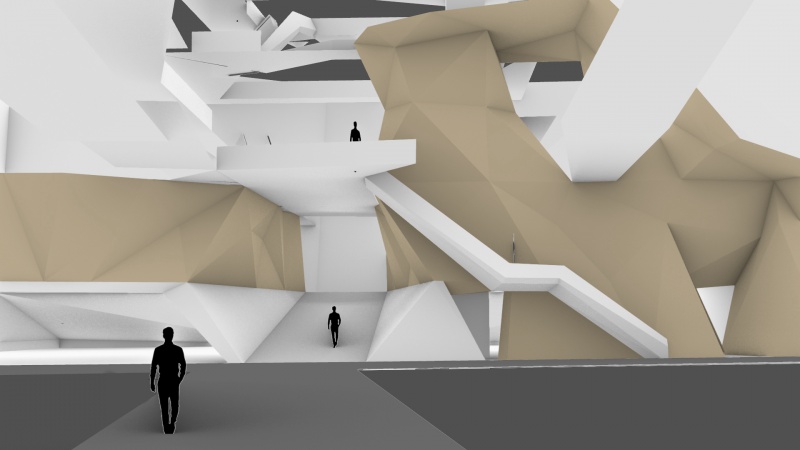

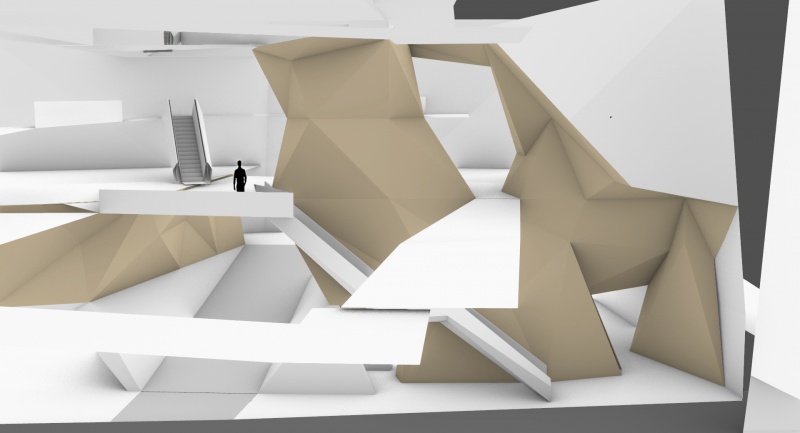

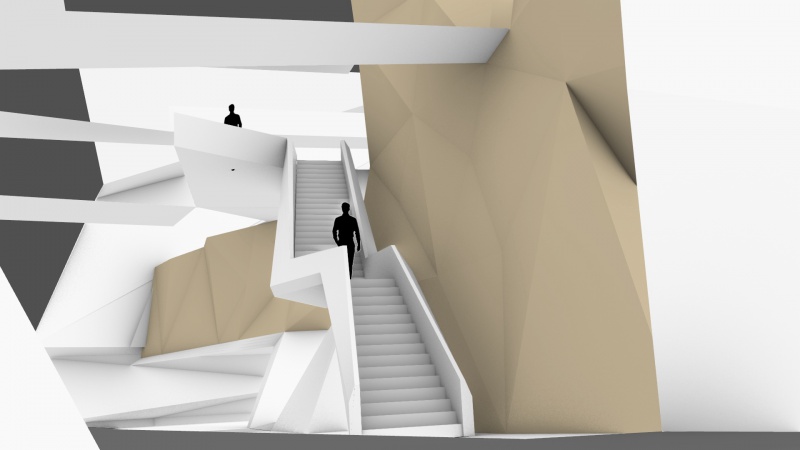

This graduation project focuses on creating small yet spacious dwellings. Offering unique dwellings to live in. Designed and build with a robotic design and assembly strategy. Creating commercial areas on the ground floor, with dwellings above it. Separating dwellings for these families from the public and increasing the feel of safety for them. While still maintaining a strong connection with the park on the south. The volumes of these dwellings have been distributed by a computational model, based on solar and view performances. Locating sleeping areas in climatic colder regions, while placing the living areas opposite of that.

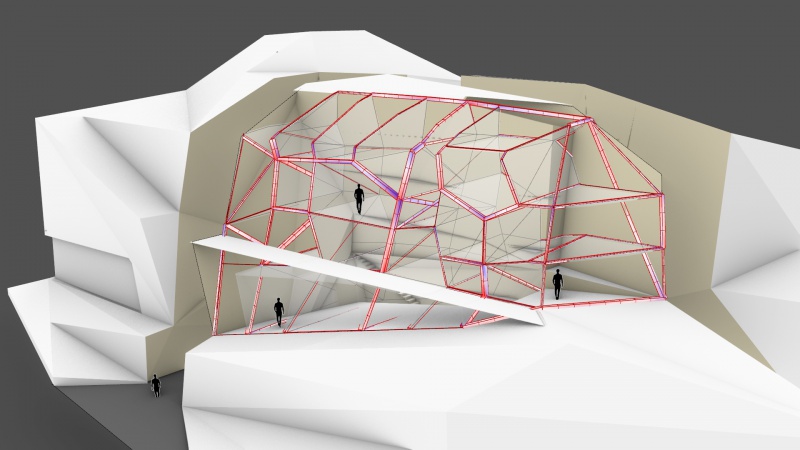

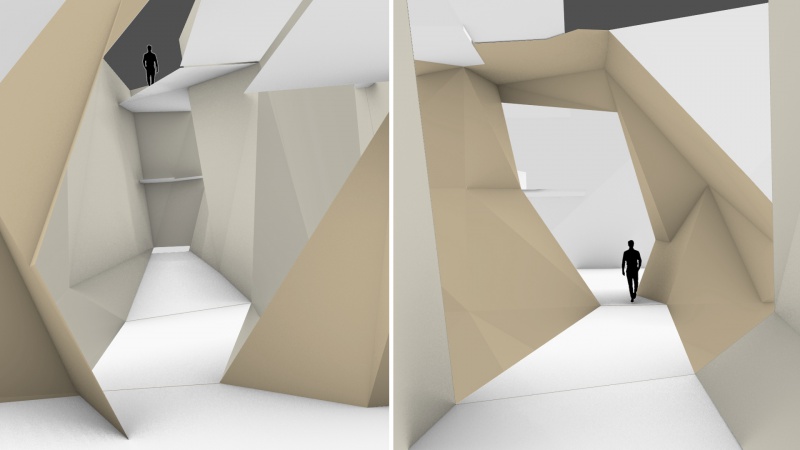

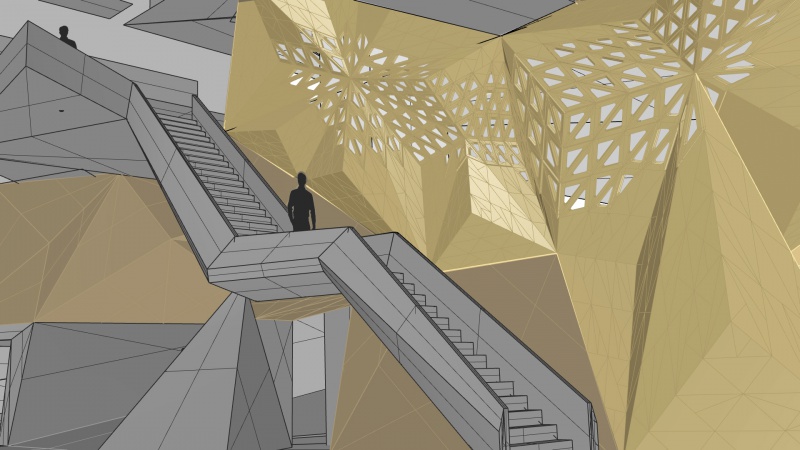

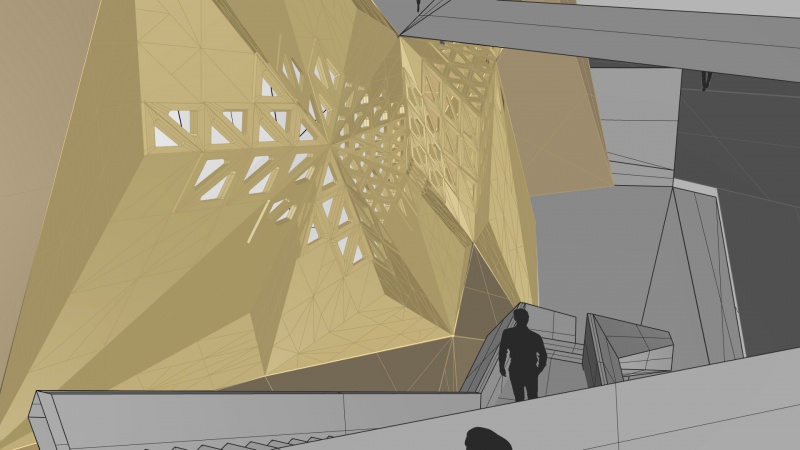

The interior offers an acoustically optimized wall to reduce noise produced by for example children. Integrating the interior paneling with that of the exterior with a spiderweb-like structure. This structure is optimized by their local forces, and thereby minimizing a material need. Throughout this structure the windows are placed that line up in between the steel tubes. Thereby providing sufficient daylight for all the spaces. Certain windows are still being able to be opened and closed manually, thereby increasing living comfort. The negative spaces between the dwellings are used for routing the electrical, pluming and ventilation. Integrating a high degree of customization with the practical needs associated with building dwellings. As last a robotic assembly strategy is being shown in combination with a local optimized node. Integrating a ‘off the shelve’ solution combined with a customized 3D printed metal node.