project04:Case Studies

Case Studies

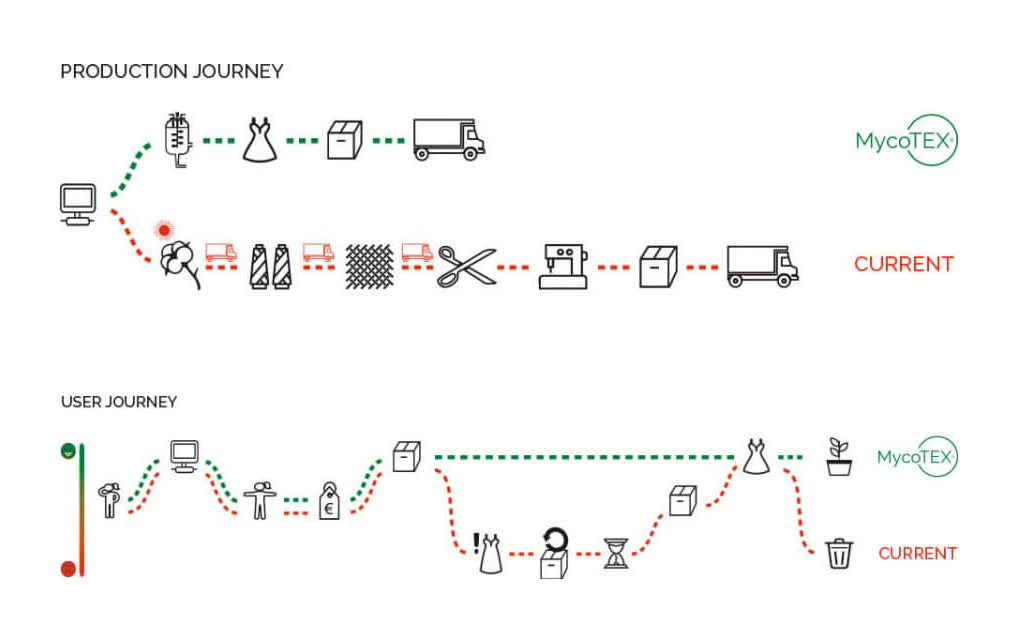

Mycotex

What is Mycotex?

MycoTex is a project focuses on the use of mycelium as a textile. With this bio-based textile the designer aims to create fashion with it.

Who designed Mycotex?

Mycotex has been designed by Aniela Hoitink. Miss Hoitink has a background in Fashion Design at the Utrecht School of Arts.

What properties does the fungi have?

In this case the designer was able to create a mycelium product with flexibility which could replace regular fabrics.

What techniques have been applied?

First of all Mycotext is produced by the usage of pure mycelium. This is done by cultivating spores of the fungi on a agar substrate. Within these substrates the designer expiremented with different fabrics where the fungus could grow on. These include wool, linen, cotton, silk, polymer based fabrics as well as fabrics combined of those materials. Besides the different materials the fabrics are based on she varied in fabric density.

To specify the the production even more, the pure mycelium was grown on agar agar and a maceraat of mycelium. Agar agar is a bio based growth medium and maceraat is a liquid where mycelium has been laid into in order to create an extract.

From these expirements the designer concluded that in order for mycelium to form the fabrics need to be loose. Because mycelium cannot grow on fabric which is tightly/densely constructed. Another problem is that she noticed that the fungus is not able to consume the fabrics, that meant she had to provide it with food whenever the test sample ran out of food. But overal she was not satisfied with the results.

Than she used another methode in order to grow mycelium. This is a method designed by the University of Utrecht and creates floating mats of mycelium. REQUIRES MORE RESEARCH. While these mats are still wet and growing she describes them to be flexible but brittle when dried. In her case she needed the material to be flexible in a dried stated and therefor she tried different fluids to make it more flexible once again, fluid like oil and vinegar. Eventually she found a way to make it flexible but she does not describe which fluid she has used for that.

What fungi has been used?

For this project the following species of fungi has been used: "Schizophyllum commune".

What qualities can be of value for my own project?

One of the intreseting things about this project is the fact that mycelium can be grown in such a way that it has a certainflexiblity. But what is more interesting is the fact that miss Hoitink has integrate lighting and a NFC chips into a bag. With the properties of mycelium being able to grow itself together it could mean that these thin textile like mycelium could be used as some sort of wall finish for a mycelium based wall. That than would mean lighting, sensors or other mechanical devices could be integrated into the wall.

More information.

For more information about MycoTex please visit the website Neffa.nl.

The photos are property of the original designers and can be found on their own respective websites

Dietz, J. Mycotex. Retrieved from https://neffa.nl/

Caroline de Roy - Antropomorphologies

Uses mycellium to create semi-transparant/translucent materials

Uses a manipulated species of Schizophyllum commune, ΔSC3.

Where is this material available and how can I use it?

Does it work in combination with other fungi or do they consume one another

Carolinederoy.nl

Studio Eric Klarenbeek - Veiled Lady 2.0

Uses mycellium to 3D print, He brings the 3d printing to the locations where the product has to be made and uses local raw materials

Bioplastics provide more pressure on agriculture.

Does it work in combination with other fungi or do they consume one another

The plant material produces oxygen during its life cycle, and our production process eliminates the necessity of heating materials in the printing process, thus reducing the use of energy. Adding up those two facts, combined with the use of local resources and production, it becomes possible to create products with a negative 'carbon footprint'. Instead of wasting less, we strive to absorb emission.

3d printing with aardappelzetmeel or bioplastics

Ericklarenbeek.com

Mycelium Tectonics - Mycelium Cotton composites

http://mycelium-tectonics.com/2015/04/hemp-simulation-02-analysis/ overview

http://mycelium-tectonics.com/2015/04/big-model-350mm-high-_-01/ Columns

http://mycelium-tectonics.com/2014/12/hemp-structure-walls/ wall fibers

http://mycelium-tectonics.com/2014/10/pleurotus-fiber/ fibers and mycelium

http://mycelium-tectonics.com/2014/11/hemp-structure-benchmark/

http://mycelium-tectonics.com/2014/09/in-vitro-mycotests/ tests

http://mycelium-tectonics.com/2014/09/in-vitro-mycotests-02/ tests

http://mycelium-tectonics.com/2014/10/in-vitro-petrimask/ tests

Mycelium-tectonics.com

Jonas Edvard - Mycelium Fiber composites

Scientific research has shown that fungi can degrade toxic and persistent waste materials such as plastics, converting them into edible fungal biomass. LIVIN Studio started working with fungi, such as Schizophyllum commune and Pleurotus ostreatus. As fungi break down the plastic ingredients without storing them in their bodies, like they do with (heavy) metals, they can be edible.

LivingStudio.com

Mycelium Textile - Mycelium Shoes

‘Growing Shoes’ shows the results of experiments in Mycelium to see how shoes can be shaped into solid and hollow models. Solid shapes function as heels, platforms and insoles of the shoe. In order to achieve these shapes, different waste streams such as coffee grounds and sawdust are used as substrates. The hollow shapes are grown pure in bottles or on fibers such as hemp and psyllium to achieve strength and structures. After harvesting, the pure Mycelium becomes a clay looking white material is then used to cover some parts of the heels or moulded onto the lasts.

http://shoedesigner.be/project/210/

http://shoedesigner.be/project/growing-shoes/

http://shoedesigner.be/project/sportive-vegan/

Jonasedvard.dk

Mycelium Textile - Mycelium Shoes

Mycelium has the natural ability to fuse together smaller pieces of organic material into a greater whole, with analogous qualities to petroleum based open and closed cell foam. Artefacts that are made from living mycelium will bind together in as short as one day if placed in contact with one another, forming an organic weld that permanently joins two objects together.

http://www.fungal-futures.com/Polyominoes-Maritime-Fungi

Mycoworks.com